Simplify measurement of manipulated tube, wire or hose.

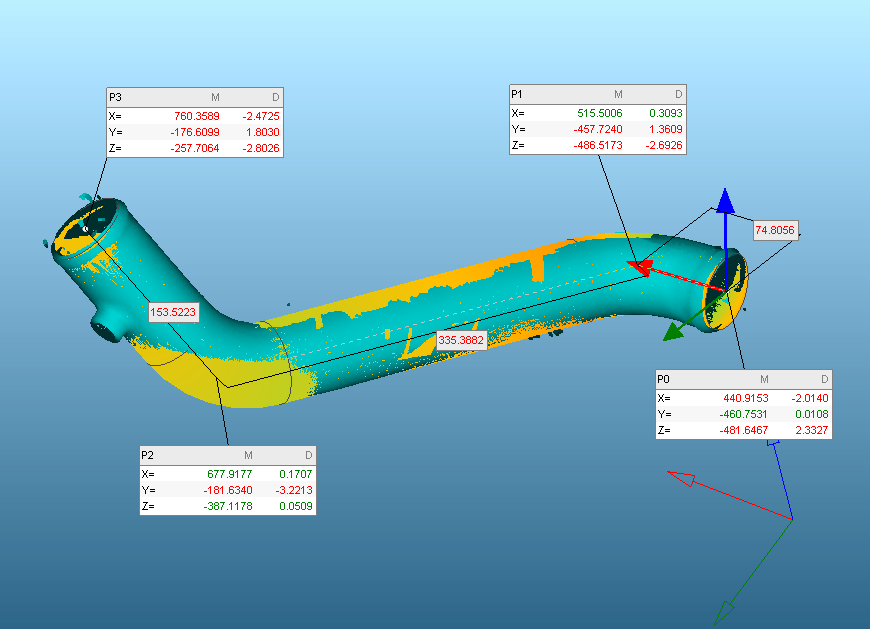

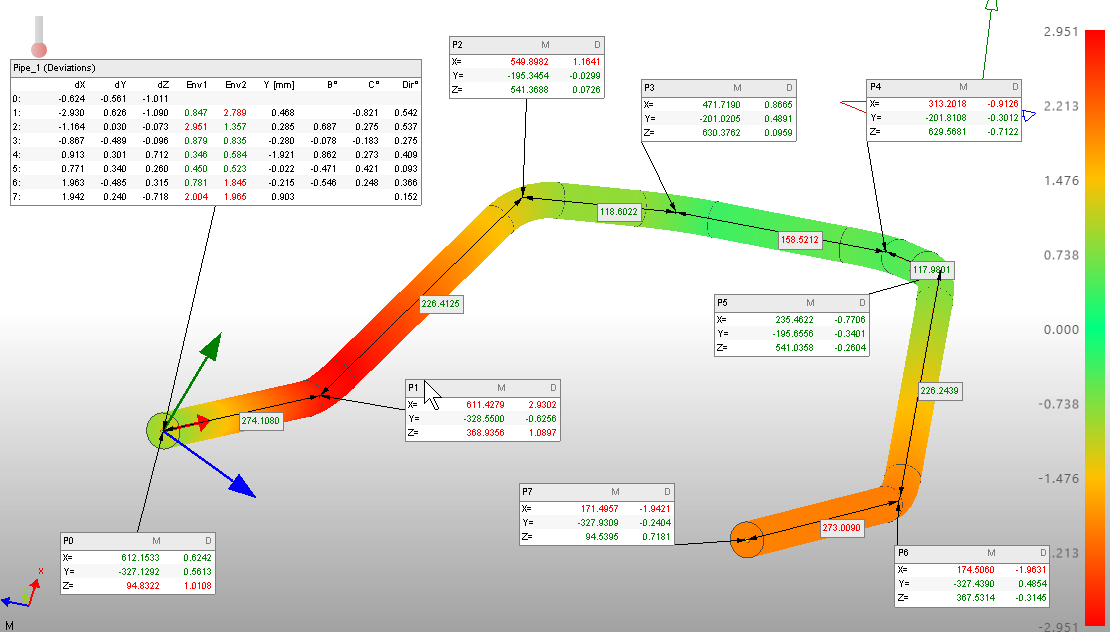

Tubes may be inspected as prototypes or against their nominal CAD model. During measurement the operator is prompted to measure the designed features of the tube, which are also highlighted in the Measure Window.

- Automatic generation of tube inspection programs

- Multiple tube datums

- Brackets Measurements

Device supported

Tubes are inspected with the support of laser forks, solid probes or point cloud scanning devices.

Direct interfaces are available to portable devices, manual CMMs, point cloud scanning devices or measurement file import.

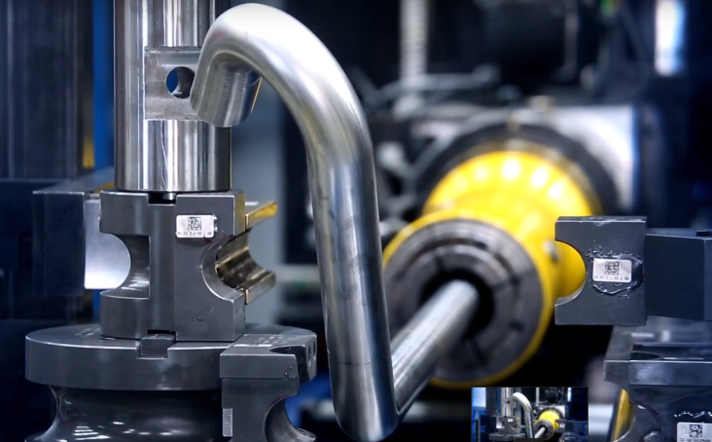

Tube bender Interface.

Axel Tube will measure and and compare the tube with its nominal model.

Bender corrections are send to multiple benders on the shop floor. We support range of bender communication interfaces.

Sending and receiving data via a network is faster and more reliable than manual corrections.

CAD data import and export.

The nominal pipe data can be imported directly from the CAD model in IGES and STEP formats as standard. For reverse engineering applications the tube results can also be exported to CAD package.